Lentils Dryer Machine

उत्पाद विवरण:

- फ्यूल टाइप Biomass Briquette coal, Gas, Diesel

- ऊष्मा स्रोत Biomass Briquette coal, Gas, Diesel

- पावर कंसम्पशन किलोवाट (kW)

- तापमान सेल्सियस (oC)

- पावर हार्सपावर (HP)

- उपयोग Ideal For Lentils Processing House, Dal mill, Pulses Mill, Ware Houses, Processors,

- मटेरियल

- Click to view more

मूल्य और मात्रा

- 1

उत्पाद की विशेषताएं

- Continuous and automatic

- हार्सपावर (HP)

- वोल्ट (v)

- One year

- Biomass Briquette coal, Gas, Diesel

- Biomass Briquette coal, Gas, Diesel

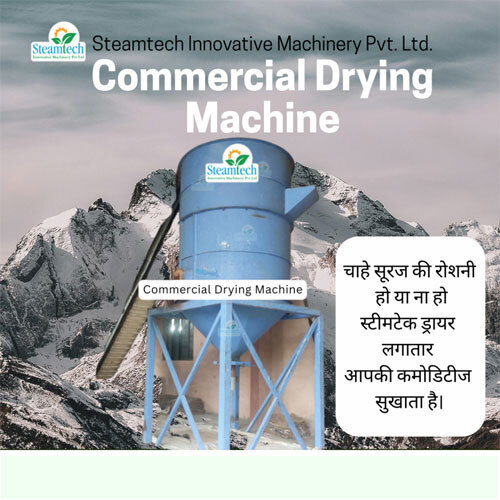

- Commercial Dryer Machine For Used industrial Drying Of Splited Dal or Lentils In Large quantity

- Ideal For Lentils Processing House, Dal mill, Pulses Mill, Ware Houses, Processors

- सेल्सियस (oC)

- Blue

- किलोवाट (kW)

व्यापार सूचना

- , , , ,

- प्रति महीने

- दिन

- Standard

- , , , , , , , ,

- ISO 9001 : 2015

उत्पाद विवरण

Steamtech Innovative Machinery Pvt. Ltd. is and established lentils dryer manufacturer and exporter of India

Lentils dryer machines typically feature a controlleddrying chamber where heated air circulates through the lentils,gradually reducing their moisture content to a safe level. Modern dryersuse automatic control panels with temperature sensors andadjustable airflow to ensure uniform, gentle drying without damaging thequality or appearance of the lentils. Depending on scale, these machines can bebatch-type or continuous flow and are available in various capacities, rangingfrom a few hundred kilograms to many tons per hour.

- Automatic operation with programmable controls for temperature, humidity, and drying time

- Construction with mild steel or stainless steel for hygiene and durability

- Three-phase power supply

- Capacities ranging from 400-500 kg/hr for medium units to more than 25 tons per day for larger industrial dryers

- Options for various fuel types (electric, wood, briquettes, coal)

Benefits

- Uniform drying ensures consistent quality for all lentil grains.

- Prevents spoilage and mold growth, extending shelf life.

- Maintains color, flavor, texture, and nutritional value.

- Energy-efficient operation with low production costs.

- Can operate year-round, in all weather conditions, even when sunlight is unavailable.

- Fast batch times and high throughput for increased productivity.

- Minimal handling and maintenance, with easy operation.

- Flexible”can process various pulses including lentils, beans, peas, and chickpeas.

- Compact design, allowing use in existing spaces or limited floor area.

Applications

- Post-harvest drying of raw lentils to commercial standards for storage and sale

- Food processing units and dal mills for quality preservation and value addition

- Drying other pulses (chickpeas, beans, peas) or grains, making the machine versatile for a range of pulse processing needs

By integrating a lentils dryer machine into your operation,you ensure consistent quality, extended shelf life, and improved profitabilityfor your pulse processing business.

Advanced Continuous Operation

The Lentils Dryer Machine employs continuous and automatic operation, significantly improving processing efficiency. The automatic system ensures uniform drying by regulating temperature and airflow. Its advanced technology fosters higher throughput while minimizing manual involvement, helping processors maintain product consistency and meet market demand efficiently.

Versatile Power and Fuel Sources

This dryer accommodates various fuel typesbiomass briquette coal, gas, and dieseloffering flexibility based on resource availability. The 18 HP power configuration and moderate electrical consumption (15 kWh at 415 volts) allow simultaneous cost savings and environmental responsibility, making it a practical choice for diverse operational contexts.

Reliable Performance and Warranty

Backed by a one-year warranty, the Lentils Dryer Machine provides peace of mind with reliable performance. Its sturdy construction and precise engineering ensure longevity and hassle-free maintenance, which are critical for high-volume processing facilities and enterprises aiming for minimal downtime.

FAQs of Lentils Dryer Machine:

Q: How does the Lentils Dryer Machine maintain optimal drying conditions?

A: The machine maintains optimal drying conditions using its automatic continuous technology, which regulates temperature (42C and 70C) and airflow to evenly dry lentils, reducing moisture content without compromising quality.Q: What types of fuel can be used with this dryer machine?

A: It supports biomass briquette coal, gas, and diesel as fuel sources, offering flexibility depending on what is available or cost-effective at your facility.Q: When is the Lentils Dryer Machine most beneficial to use?

A: The machine is particularly valuable during peak harvest or processing seasons when rapid and consistent drying is crucial to prevent spoilage, support high throughput, and maintain product quality for storage or export.Q: Where can this dryer machine be installed?

A: It is ideal for lentil processing houses, dal mills, pulses mills, warehouses, as well as by processors, exporters, manufacturers, and suppliers throughout India. Its compact yet efficient design fits seamlessly into both new and existing processing lines.Q: What is the drying process like with this machine?

A: The drying process involves loading lentils into the automatic system, choosing the desired temperature, and the continuous operation evenly dries the product, protecting it from over-drying or under-drying and preserving its nutritional value.Q: How does usage of this dryer benefit lentil processors and exporters?

A: Using the dryer accelerates moisture removal, ensures uniform drying, decreases spoilage risk, and complies with storage and export standards, enhancing product value and supporting business growth.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+