Product Description

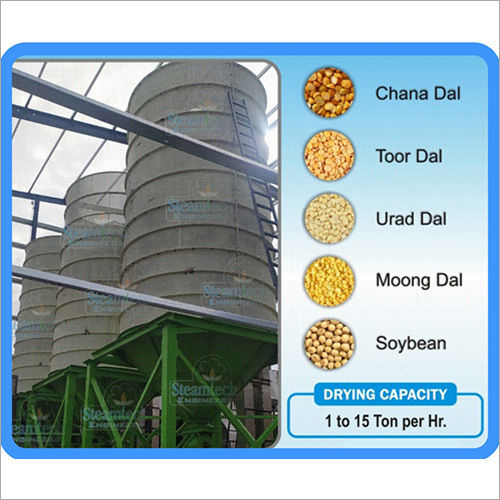

Dal Dryer by Steamtech Innovative Machinery Pvt. Ltd. is a specialized drying system that dries dal (lentils) in a continuous and automatic process quickly. These dryers are highly advanced and gives desired output. The single pass drying system of the dryer machine makes the dryer super reliable and keeps up accurate moisture level to the dal (lentils).

Steamtech's Dal Dryer is designed to provide uniform, fast, and hygienic drying for all types of pulses, including toor dal, moong dal, chana dal, urad dal, masoor dal, and more. Our advanced technology ensures precise temperature control, energy efficiency, and minimal breakage, making it an ideal choice for dal processors looking for a reliable drying solution.

Unique Features of Steamtech Dal Dryer

Advanced Temperature Control Ensures consistent drying without overheating.

Fuel-Efficient Design Reduces drying costs with optimized energy consumption.

Automated Operation Minimizes manual intervention and labor costs.

Hygienic Drying Process Prevents contamination and maintains product quality.

Customizable Capacity Available in different sizes to suit processing needs.

Weather-Independent Drying Works efficiently in all seasons, unlike sun drying.

Robust Construction Built for durability and long-term performance.

25 Benefits in One Word Each

1 Uniformity

2 Energy-Saving

3 Time-Efficient

4 Cost-Effective

5 Hygienic

6 Low-Maintenance

7 High-Capacity

8 Gentle Drying

9 Fuel-Efficient

Customizable

11 Automation

12 Minimal Breakage

13 Weather-Proof

14 Consistency

15 Space-Saving

16 User-Friendly

17 Eco-Friendly

18 Fast Processing

19 Dust-Free

20 Reduced Moisture Variations

21 Extended Shelf Life

22 No Overheating

23 Improved Quality

24 Smart Technology

25 Enhanced Productivity

Usage

Drying of toor dal, moong dal, chana dal, masoor dal, urad dal, and more

Suitable for industrial-scale dal processing

Ideal for exporters, wholesalers, and food processing industries

Application

Dal processing mills

Food production units

Exporters of pulses

Large-scale agro-processing units

Company Address:

Steamtech Innovative Machinery Pvt. Ltd.

Rajkot, Gujarat, India

For inquiries, visit: www.steamtechdryers.com

Upgrade your dal processing with Steamtechs advanced drying solutions today!

#daldryer #lentilsdryer #daldrying #daldryermachine #industrialdryer #daldryermanufacturers

Efficient Gas-Fired Drying TechnologyThis Toor Dal Dryer Machine utilizes advanced gas-fired technology, ensuring rapid and uniform drying of pulses. The conical design enhances heat distribution, optimizing the drying process for maximum yield and product quality. Capable of operating on both LPG and PNG, it offers flexibility to match your facilitys resources.

User-Friendly Industrial DesignManufactured with user convenience in mind, the machines conical structure stands 23 feet tall, allowing for optimal airflow and moisture extraction. Its robust design accommodates both industrial and commercial needs, supporting large batch operations to increase productivity.

Consistent Results and Reliable OperationThe dryer maintains a steady temperature range of 70 to 80C, powered by a reliable 25.5 HP engine. Backed by a one-season warranty, it ensures minimal downtime and consistent quality throughout high-volume drying cycles for toor dal and similar pulses.

FAQs of Toor Dal Dryer Machine Gas Fired Conical shape:

Q: How does the gas-fired conical dryer machine work for toor dal?

A: The machine heats air using LPG or PNG, which is then circulated uniformly through the conical chamber to gently and efficiently dry toor dal at controlled temperatures of 70 to 80C, ensuring even and rapid moisture removal.

Q: What are the advantages of using this dryer for industrial and commercial applications?

A: This dryer offers reliable, large-capacity performance with consistent temperature control, reducing drying time and ensuring uniform quality. Its robust, conical design maximizes airflow, making it ideal for high-volume operations in pulse processing industries.

Q: When should I choose a gas-fired dryer over an electric dryer?

A: A gas-fired dryer is preferable when consistent high temperatures and efficient energy consumption are required, especially in locations with reliable LPG or PNG supply, or where electricity costs are comparatively high.

Q: Where can this machine be installed and what are the space requirements?

A: The dryer can be installed in industrial or commercial pulse processing units with sufficient ceiling height and floor space (at least 8 ft x 8 ft footprint and 23 ft height clearance) to accommodate its dimensions and ensure safe operation.

Q: What is the typical process for drying toor dal with this machine?

A: The process involves loading cleaned toor dal into the machine, setting the desired temperature (between 70-80C), and initiating drying. Heated air circulates throughout the chamber, and the process continues until the pulses reach optimal dryness, after which they are discharged.

Q: How do I benefit from the one-season warranty provided?

A: The one-season warranty covers operational defects and manufacturing issues, offering peace of mind during peak production periods and minimizing unexpected expenses related to machine breakdowns.

Q: Can the machine handle other pulses aside from toor dal?

A: Yes, while optimized for toor dal, the versatile design allows use with a variety of pulses, provided they have similar drying requirements, making it suitable for multipurpose industrial and commercial pulse drying.