Call Us : +918511146990

- Home Page

- Company Profile

-

Our Products

- Maize Dryer

- Dal Dryer

- grain Drying Plant

- Mild Steel Semi Automatic Grain Dryer Machine

- Flat rice khichiya Papad Dryer Machine

- Maize Dryer Machine Agriculture Dryers

- Peanut Drying Plant

- Paddy Dryer

- Pulses Drying Plant

- Soybean Dryer Machine Mild Steel capacity 10 ton

- Mahua Seed Dryer Plant

- Rice Paddy Drying Plant

- Cottonseed Drying Plant

- Multi Commodity Dryer

- Industrial Dryer Machine For Grains

- Neem Seed Drying Plant

- Sambrani Dhoop Cup Dryer

- Paddy Dryer Plant

- Maize Seed Dryer Machine

- agarbatti heat dryer

- Dhoop stick Dryer Machine

- Agro Commodity Drying Plant

- Hot Air Generator

- Computer Sambrani heat dryer

- belt dryer

- Soybean Belt Dryer (Gas Fired)

- Soybean Belt Dryer (Agro Waste Fired)

- Fryums Dryer gas fired

- Dal Dryer Agro Waste Fired

- Fryums Dryer Machine

- Belt Dryer

- Soybean Belt Dryer (Electrical)

- Fryums Dryer

- Cotton Seed Dryer Machine

- Soybean Belt Dryer (Diesel Fired)

- Neem seed dryer

- Maize Belt Dryer (Gas Fired)

- Maize Belt Dryer (Diesel Fired)

- Fryums Dryer Gas Fired

- RICE FLOUR FINGER DRYER fryums dryer

- Continuous Type Hot Air Dryers

- Medicinal Leaves Dryer Machine

- tray dryer

- tray dryer with chamber

- Incense Stick Dryer 250 Kgs Agro Waste Fired

- Agarbatti Dryer

- Dhoop Stick Drying Plant

- Incense Stick Dryer 1000 Kgs Electric

- Incense Stick Dryer 1000 Kgs

- Incense Stick Dryer 1000 Kgs Agro Waste Fired

- Incense Stick Dryer 250 Kgs Electrical

- Incense Stick Dryer 1000 Kgs Gas Fired

- Incense Stick Dryer 500 Kgs Electrical

- Incense Stick Dryer 32 Kgs Electrical

- Incense Stick Dryer 125 Kgs Electrical

- Incense Stick Dryer 125 Kgs Gas Fired

- Incense Stick Dryer 250 Kgs Diesel Fired

- Incense Stick Dryer 125 Kgs Diesel Fired

- Incense Stick Dryer 125 Kgs Agro Waste Fired

- Incense Stick Dryer 250 Kgs Gas Fired

- Commercial Agarbatti Heat Dryer for 125kg

- Agarbatti Dryer Machine

- Vertical Flow Dryer

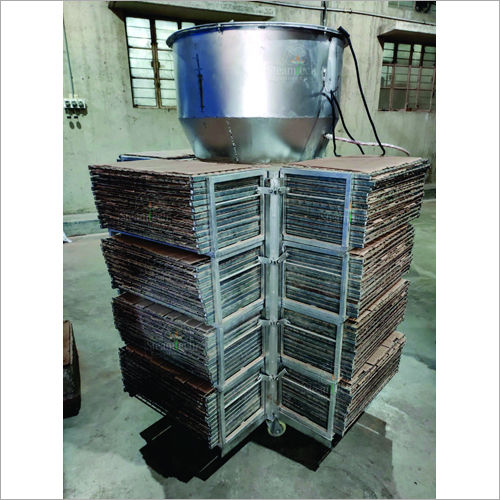

- Conical Dryer

- Grain Dryer

- Stainless Steel Grain Dryer Machine

- Grain Dryer For maize, paddy, soybean, seeds

- Mild Steel Automatic Grain Dryer

- Seed Dryer Machine for grains

- Small Grain Dryer Machine

- Industrial OEM Maize Dryer Machine

- Mild Steel Multi Commodity Dryer

- Steamtech Grain Dryer Machine

- Grain Dryer Machine

- Soybean Dryer Machine

- Paddy Dryer Machine

- Continuous Grain Dryer Manufacturers &

- Mild Steel Grain Dryer Machine

- Advance And Highly Efficient Paddy Dryer For Raw Paddy

- Lentils Dryer

- Fryums Belt Dryer

- MUlti Pass Dryer

- Contact Us